Goal

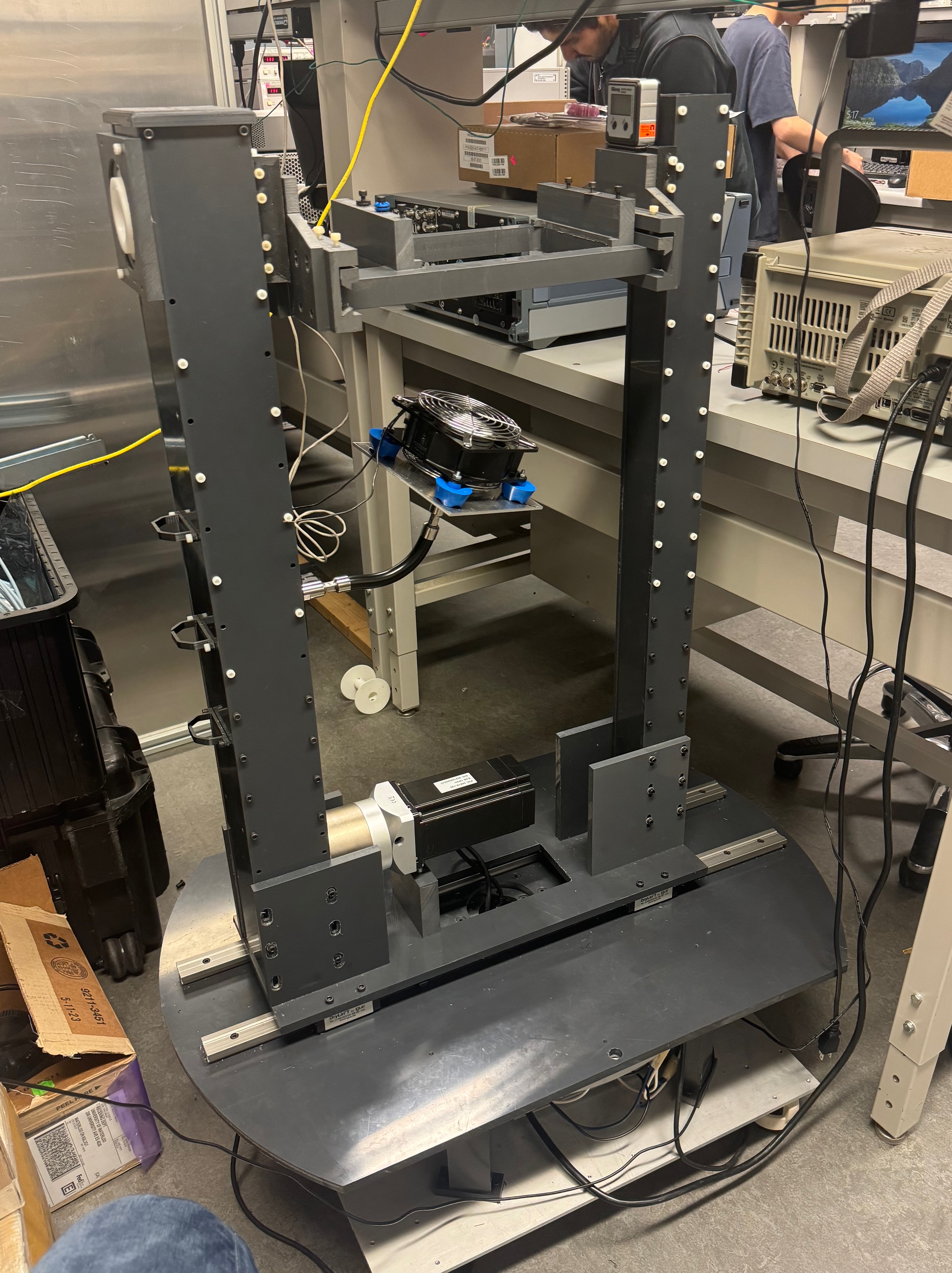

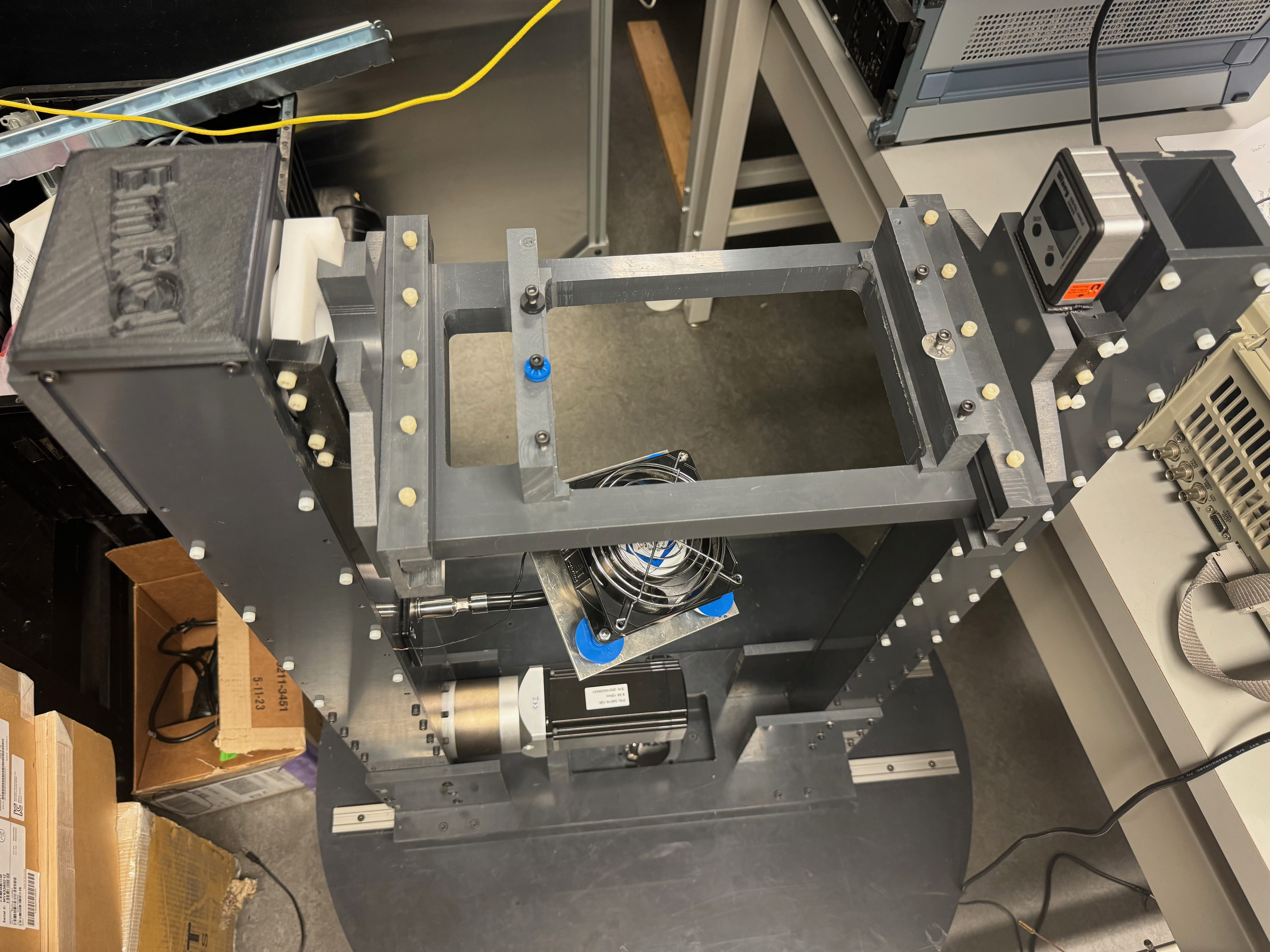

For this project, I was to design and implement the electronics, motor control, and software integration for a multi-axis antenna positioner. The positioner needed to be controllable to specific positions that would be used on devices. I needed to consider interference, ventilation, vibration, Matlab compatibility, weight requirements, and centralized rotation. I was given the mechanical structure, motors, and gears to start with, but there was no access to historical files or documentation.

Method

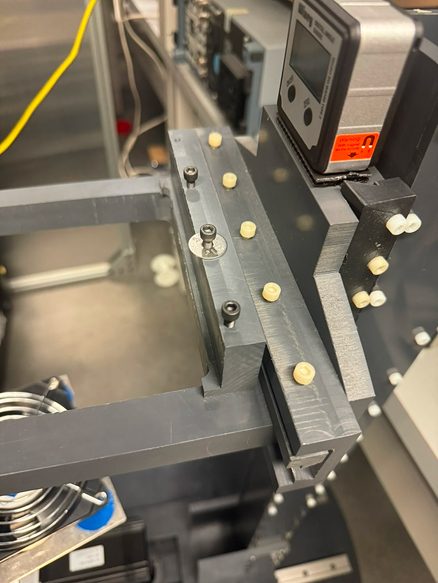

I began by reverse-engineering the incomplete system to understand the intended functionality and identify missing or incompatible components. Upon going through this, I realized that the motor drives were incompatible with the selected motors. I ordered the correct motor drives. I also had to order a custom missing pulley and determine the supportable weight by calculating loading strength using the motor torque.

Next, I worked on the control of the system. A Smoothieboard, which is a 3D printer controller, was used to control the motor drives and allowed for precise positioning when used in combination with the gearboxes. I did all of the electrical wiring required between motors, motor drives, the Smoothieboard, and the AC/DC converter. I wrote Matlab functions and code to communicate with the board via Serial-over-USB. I implemented offsets and correction factors to account for the gearboxes and their inherent backlash. I added a homing ability to allow for easy referencing. I also added a software-based kill switch which ensured the positioner would stop moving immediately. The software allowed the user to control the device to specific azimuth and elevation angles. They could also change the reference position, return to previous locations, and get the current position.

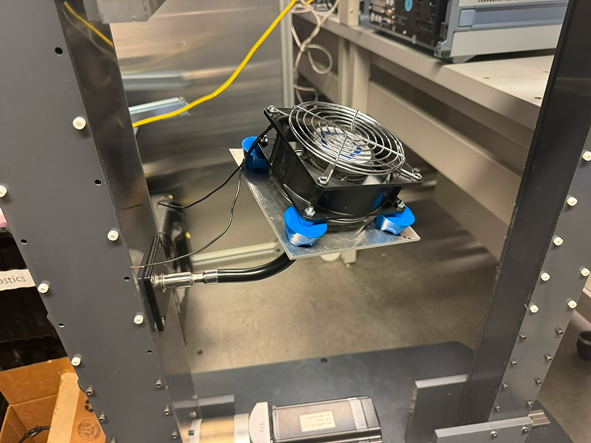

I ensured that all rotation occurred about the centralized antenna. I also improved the ventilation, set-up a manual re-calibration method, reduced the on panel fan vibration, added an adjustable fan, and improved the wire management.

I wrote a guide explaining the positioner, its limitations, how to use the software, and explaining common problems. It also included a full BOM.

This project was done using Matlab.

Results

- Implemented working positioner for the lab without access to previous files or documentation.

- Significantly improved upon design to meet all requests by lab members.

- Final cost was $800 compared to over $15,000 for commercial positioners

- Similar capabilities in weight, communication and software.

- Commercial positioners have slightly better precision.

- Achieved 0.5 degree precision.

- Actively used by researchers in the lab for antenna calibration and testing

- See the video for the positioner in action!