Responsibilities

Positioner Development

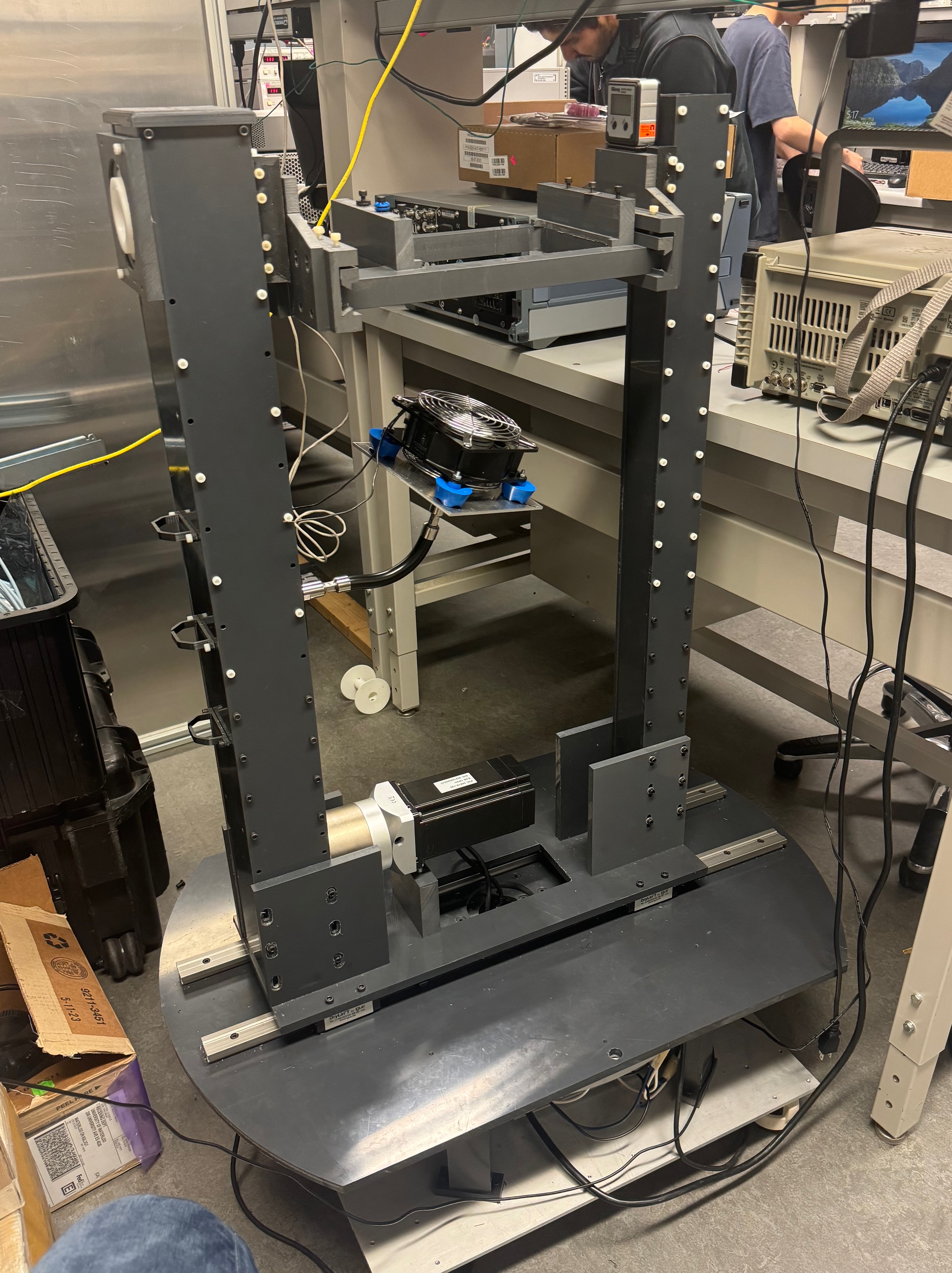

At the UWaterloo EmRG Lab I was tasked with building a motorized 3-axis antenna positioning system for active FR2/FR3 over-the-air RF testing. There were various specifications that I needed to meet including size, supportable weight, cost, vibration, thermal ventilation, and antenna-centric rotation. The mechanical aspects of the positioner were already present from a previous co-op student. However, there was no documentation, various missing parts, and improper components.

I needed to reverse-engineer the positioner, procure new components, and integrate the belt-driven motors, drives, power electronics, and control software/hardware. I did all of these entirely independently.

I also spoke directly with the RF antenna engineers to meet their exact requirements for the positioner. I communicated the progress of the positioner often, and adapted to their suggestions and requests.

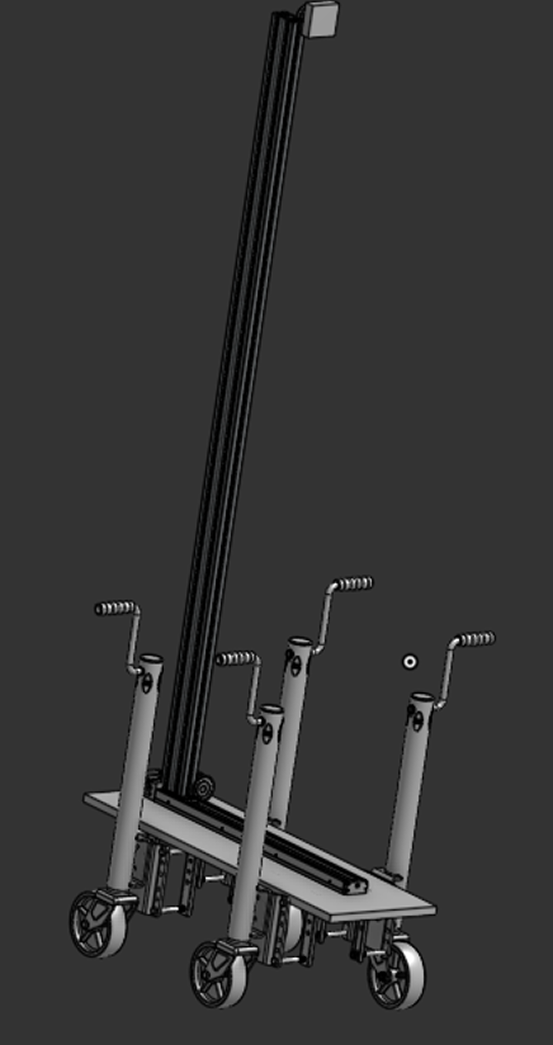

Polarization Positioner Design

In addition to building the positioner, I designed a lightweight, high-repeatability polarization positioner for precise 90° switching with minimal mechanical play. The positioner needed to have motor controlled distance travel, manual height adjustments, high-precision and repeatable 90 degree rotation, and no metallic components near the device connection.

I made a preliminary design, which had very high capability, but was far too expensive. Upon receiving feedback and collaborating with the group to decide which functions could be reduced, I redesigned the positioner. By limiting the range of motion, changing beam material, and utilizing a pulley system, I was able to reduce the cost by half. My design met all constraints and much of the criteria that were laid out for me. I directly explained the functionalities that were impacting cost the most, and provided alternatives with their respective tradeoffs.

Projects

Results

- Received Excellent performance rating - indicating all performance expectations in respect to output, quality standards, delivery of goals, and assignments were exceeded, and manager was delighted.

- Implemented working positioner that is used in the lab without access to previous files or documentation.

- Significantly improved upon design to meet all requests by lab members.

- Delivered positioner that was significantly cheaper ($800) than commercial alternatives ($15,000) with similar performance.

- Designed a second system meeting all of the provided constraints.

Skills

- Communication

- Problem Solving

- Software (Matlab)

- Hardware

- Project Management

- Mechanical Design

- Electrical

- Motor Control / Motion Systems

- Electronics Integration

- Cost Optimization